Breakthrough in bulk production of Indigo spray dyeing

DyStar and RotaSpray successfully developed their indigo spray dyeing procedure for production on a bulk level which allows denim producers to significantly reduce their environmental impact.

The solution was first introduced at ITMA Milan in 2015. Since then, DyStar and RotaSpray have been working together to develop it further and make it available for bulk production in important Denim markets like Turkey, India and Pakistan. With the recent breakthrough, they are now announcing a salt-less dyeing solution for the denim industry. This new technology is awarded important ECO certificates and offers high flexibility for dyeing small lot sizes, reduced water usage and effluent discharge lower impact on yarn in the dyeing process and simplified recipe changes.

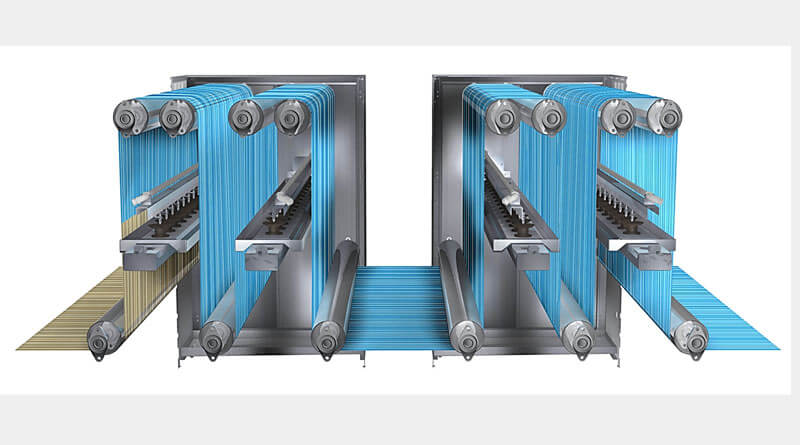

The new Spray dyeing technology combines DyStar Indigo Vat 40% Solution, Sera® Con C-RDA (a unique organic reducing agent) and the effective optimization of spraying parameters of the EPO patented RotoDyer® and the RotoCoater® spraying technology. Although rotary atomizers have been established for several decades in the textile industry they were mainly used for rewetting textiles with moisture. But recent cost pressure and a global demand for more sustainable solutions were motivators for the R&D of the industry and led to the recent technology leap.

On sheet dyeing ranges (slasher), with process and layout modifications, coatings including DyStar Indigo Coat, Cassulfon®, Remazol®/Levafix® and Imperon® dyes can be applied by spray dyeing as well. The spray application of fixing agents and oxidation chemicals can be integrated into sheet dyeing (slasher) as well as rope dyeing machines.

DyStar Indigo Vat 40% Solution has always been a step ahead of the cleanest dyeing process on the market for the denim industry. This is another innovative step to offer best-available technology to the industry.

About RotaSpray GmbH

RotaSpray is manufacturing rotating atomizers for tailor-made conceptions in dyeing and finishing of warp yarn, fabric and NONWOVEN as well.

The Company is founded in 2013 and R&D was finished in 2016 with the result of marketing the machinery in important DENIM markets in priority. Sales and marketing as well as software development is in-house and allows solutions based on customer needs. The experience of more than four decades in textile industry leads to contacts all over the world. Spray units in China, Indonesia, Turkey, India and Pakistan are producing successful with very positive feedback and are used to create innovative products based on sustainable and cost-efficient conditions.

About DyStar

The DyStar Group is a leading dyestuff & chemical manufacturer and solution provider, offering customers across the globe a broad portfolio of colorants, specialty chemicals, and services. With a heritage of more than a century in product development and innovation for the textile industry, DyStar also caters to multiple sectors including the paints, coatings, paper and packaging industries. Its expansion into the food & beverages and personal care sectors reinforces the company’s position as a specialty chemical manufacturer. DyStar’s global presence offers customers reliable access to experts from offices, competence centers, agencies and production plants spanning over 50 countries.

DyStar’s key service divisions assist brands & retailers and their industry partners from their first inspiration throughout the entire supply chain to ensure that they meet stringent quality and ecological specifications, reduce costs and shorten lead times. We offer state-of-the-art color communication through CSI; textile and ecology testing through Texanlab; ecology and environmental advice, supply chain auditing and consulting for RSL compliant sustainable processes through Sustainable Textile Solutions group.

The DyStar econfidence® program is designed to provide assurance to textile customers that the dyes and chemicals supplied by DyStar comply with legal requirements. econfidence® also provides expertise so that selected products are compliant with voluntary Restricted Substances Lists (RSLs), including those of brands and retailers. Backed up by the most extensive eco-testing program of any chemical supplier in the industry, econfidence® supports long-term partnerships along the supply chain and fosters a more sustainable textile production.

Fully dedicated to quality management, DyStar is an ISO9001 British Standard Institution (BSI) certified company. Our products for food & beverage undergo additional certifications, such as FPA, GFSI (SQF 2000), Kosher, Passover, and Halal. Each batch of certified food colors is tested and approved by a United States Food and Drug Administration (FDA) laboratory.

Visit www.DyStar.com / www.CSIColors.com for more information.